Custom IC Test Sockets & Thermal IC Test Solutions

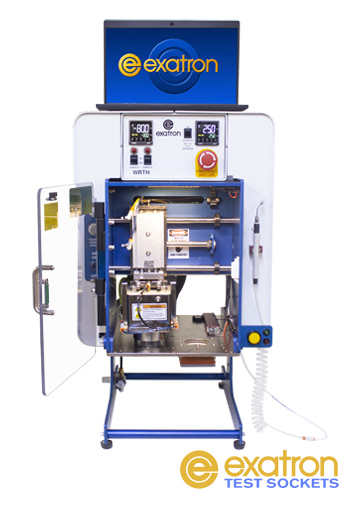

Exatron designs and manufactures Custom IC Test Sockets, advanced Thermal Test Sockets and advanced Thermal Forcing Test Solutions, in San Jose, California, USA, for hand test, benchtop test and ATE automated test handlers and equipment. "Exatron Test Sockets" specializes in Copperhead® Thermal IC Test Sockets featuring Exatron Diamond Particle Interconnect (EPI) contact system and Direct Conduction Temperature Forcing Test Systems featuring the Wide Range Thermal Head (WRTH). Low and high temperature test sockets from -100°C up to +150°C, +250°C and +300°C probes or diamond particle contacts. Exatron is highly regarded in the industry for the finest automated computer controlled test handlers and equipment for lab test and production since 1974. Exatron Test Sockets brings this tradition of expertise and quality to your demanding semiconductor integrated circuit (IC) device testing needs.

Exatron’s new thermal IC Test socket, Copperhead®, is a massive new improvement in the state-of-the-art for thermal test socket design. Copperhead® IC temperature test sockets are designed for truly exceptional thermal performance. Hand test through production testing, this solid copper top test socket can match any existing footprint. Works beautifully with all Exatron thermal test solutions and handler applications as well as many others.

NOTE: New Model with advanced features. Temperature Forcing Semi-Automatic Tabletop Mini Handler

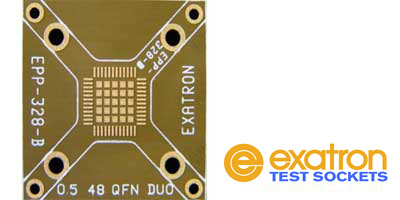

Exatron's custom test sockets are made to suit your exact application. DC to RF, low to high temperatures available from -100°C up to 300°C, single contact and Kelvin, non-magnetic, military hardened coatings and more. Exatron's custom IC test sockets are designed to cover the entire range of your needs plus work over the entire Exatron product range from hand test and benchtop testing all the way through ATE automatic handler test and production. Send us your (POD) package outline drawing and your requirements and get a quote.

"A far superior contact technology." Capacitance and inductance near zero, tested up to 40 GHz, contact resistance under 3 milliohms, -100°C to +300°C, low contact pressure, 0.4 mm pitch and higher, up to 1,000,000 cycles. About the same electrical characteristics as a solder joint, possibly better; just about says it all.

The next generation of Prototype Engineering Work Stations (PET-4D), designed to replace dated thermal streamed air test systems in the hand testing of individual electronic devices under controlled conditions. Advanced design -55°C to +155°C (-80°C to +175°C hardware capability) +/-0.5°C control, no frost buildup, conduction heating, direct contact. Time saving and accurate with outstanding performance.

When you don't need something large and expensive to get the job done, Exatron has a variety of small, mini desktop or tabletop handlers, including the new Label and/or Ink Dot Pick & Place Handler and other equipment such as manual and automated tape and reel, and laser enclosures and more. These units are known for ultra high quality and great value at relatively low cost and designed to fit comfortably on the top of your desk, bench, or table. All Exatron equipment is fully designed and made in the USA since 1974.