Diamond Particle Interconnect (PI)

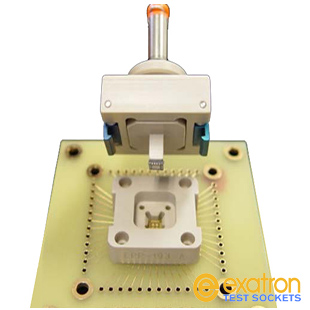

Exatron's Diamond Particlization Process for IC interconnection is a modern state-of-the-art test socket contact system technology that can also be applied to other electronics applications. This contact system eliminates many of the issues with traditional spring probes and inherent issues with rocker type contacts such as the wearing out of board pads and traces. It is ideally suited for IC test sockets and any interconnect between surface mount devices and load boards, testers, programmers and other repeat-insertion applications. The wide range of applications include IC test sockets, CSP sockets, universal test sockets, MEMS sockets, RF zero sockets, multisite sockets, as well as high density interconnects, replacement handler contacts and EMI shielding. PI can also be plated directly onto PCBs for a variety contact needs.

Zero Inductance, Zero Capacitance, Zero Resistance

Yes, this is possible now. Plus a very wide temperature range from -100°C to +300°C. With a total interconnect of less than 0.001” between DUT lead and test circuit trace, the PI contact system is the only contactor method with effectively Zero Inductance, Zero Capacitance and Zero Resistance. Diamond Particle Interconnect contact system has a cycle lifetime of up to one million insertions and more. PI test sockets are easy to clean Pb free IC test sockets. Pitch can be as low as 0.2mm for your chip scale and other packages. You can have up to 40 GHz for RF high frequency test sockets. PI is exceptional for CSP, MEMS, high density mass interconnects and for replacement contacts for all handler models. The same socket can be used from hand test, benchtop testing or automated lab test all the way through production.

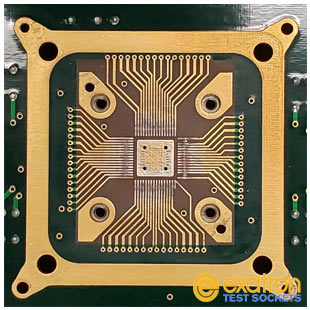

PI Contact System Technology

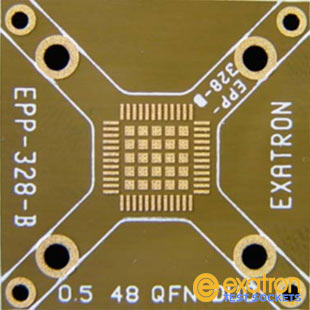

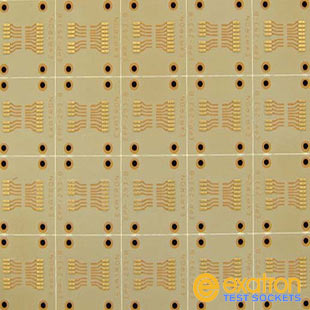

PI technology begins with 15 micron metal coated diamond particles. These diamond particles are selectively electroplated onto the substrate area using a modified PCB process. PI creates a “micro bed-of-nails” with 50,000 contact points per square inch. It makes a gas-tight electrical contact by penetrating the oxide layer rather than the traditional wiping action of standard contactors. PI produces contact resistance below 3 milliohms.

Electromagnetic Shielding

EMI Shielding is one of many applications. Other possibilities are:

- Universal Test Sockets

- Standard Test Sockets

- CSP Sockets

- MEMS Sockets

- RF “Zero” Sockets

- Multi-Site Sockets

- Replacement Handler Contacts

- High Density Interconnect

- BeCu Spring Contacts

- Plated Directly to your board

Particle Interconnect Test Sockets

- Built-in mechanical compliance with the shortest contact height of any socket on the market today.

- Optional selectively plated bumps.

- 0.1mm of mechanical compliance minimum.

- Less than 0.3mm thick.

- -100°C to + 300°C temperature range.

- Reliable performance, durable construction.

- Tested up to 40 GHz in RF applications.

- Matches any existing socket footprint.

- Sold in sheets or as part of a complete test socket so you can have many replacement interposers on hand.

- Many material choices available

- PI works with MLF, QFN, and LCC and more leadless packages and all leaded packages 0.4mm pitch and up.

- PI can be made to almost any footprint configuration and tooling pin or bolt pattern.

- Easily adapts to, renovates or replaces any rocker-type test socket footprint.

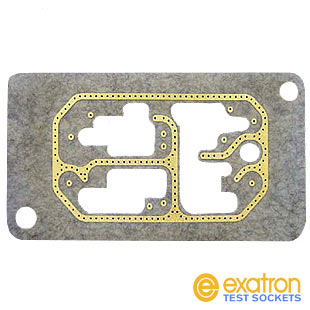

Socket Saver

Something to keep in mind that may save the day. The above image shows what can happen when your expensive rocker style test socket wears out the traces on your very expensive printed circuit board. The cost and time to respin the PCB and replace the expensive rocker test socket can become a difficult issue. Exatron's Diamond Particle Interconnect (PI) Socket Saver® can now come to your rescue! Self-cleaning, wiping, roll, rocker-type contacts are well known for wearing out the PCB pads and traces. PI cleans without wiping and wearing out boards and is a much better contact system. Socket Saver is a PI sheet of Kapton with Diamond Particle Interconnect material plated longer on the bottom to connect to areas that are not worn out on your PCB. Socket Saver is used as a shim under the socket. This will restore your socket operation to like new condition and can save an expensive board spin. Rejuvenate with the Socket Saver. Bring worn out expensive printed circuit boards back to life and save your expensive socket and PCB. Don’t spin, think Exatron "Socket Saver" instead.

Custom IC Test Sockets & Thermal Solutions

2842 Aiello Drive

San Jose, California, 95111

Contact Us Today!