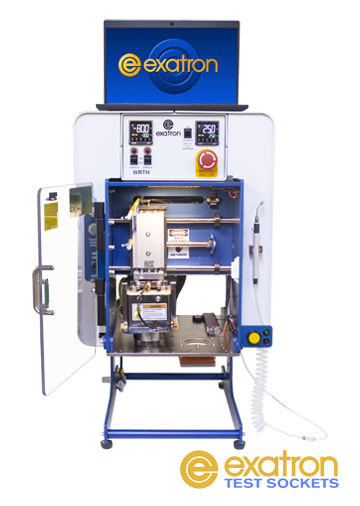

This new advanced solution Semi-Automatic Mini Thermal Handler Features a Direct Contact Refrigeration Temperature Forcing System without Frost, or Streamed Air ESD concerns and with No Expensive fluids to spill. The PET-4D has better performance and functionality than Streamed Air or Peltier systems. The Guaranteed Working Range -55°C to +155°C (-80°C to +175°C Equipment capable).

SAN JOSE, CA – Adding to its already wide range of automated thermal test advanced solutions, Exatron recently introduced the PET-4D benchtop temperature forcing system, a semi-automated thermal forcing test station with a guaranteed working range of -55°C to +155°C (-80°C to +175°C). It allows hours of hands-free testing without needing to return to room temperature between tests and with zero frost buildup. The PET-4D features the exact same Wide Range Thermal Head (WRTH) as Exatron’s pick and place handlers and utilizes the same direct contact thermal forcing temperature test method, allowing +/- 0.2°C temperature control and accuracy. Precisely directed purge air shortens soak times and, along with pneumatic shutters which only open during insertion/removal and testing, eliminates frost buildup during cold testing. Even at -80°C, no frost appears on the test head or the socket. Overall, the PET-4D is an efficient and easy temperature test solution, offering 60 W of cooling power at -55°C, requiring no fluids, and able to fit on a standard work bench. (Dimensions are approx.. 16” W, 19” D, 26” H, not including attached chiller unit) Operation is simple. Open the door and push and hold the button to open the shutter. Place a device at the socket and release the button to close the shutter. Close the door. The WRTH slides over and lowers to the DUT to begin testing. Soak times are computer-controlled by Exaton’s proprietary software, so testing never starts before DUT is at the desired temperature. After test, sort result is indicated by a green (pass) or red (fail) light. Open the door, press and hold the button to open the shutter, remove the device, and repeat the process as needed. Keeping with Exatron’s versatile building block design philosophy, the PET-4D is easily adaptable from soft to direct docking. Simply remove the legs and attach to the same docking hardware used on Exatron engineering and production volume handlers. One can swap the docking hardware from a handler to the PET-4D in a matter of minutes. The PET-4D continues Exatron’s history of thoughtful and effective design, offering a powerful thermal forcing test solution in a compact, easy-to-use package. Since 1974, Exatron has created custom handling, testing, thermal test sockets and marking systems for nearly any application using their modular building block approach. Exatron controls all aspects of handler design, test socket design, manufacture, and production on site in San Jose, CA, including software engineering. This centralization of production allows seamless integration of hardware and automation software and continuous oversight at every stage of production. Contact Us Today!

PET-4D Direct Dock Mode

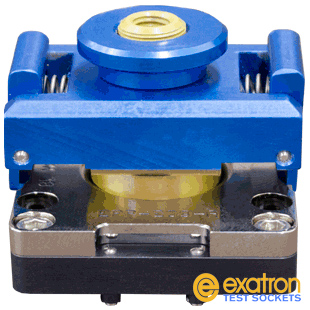

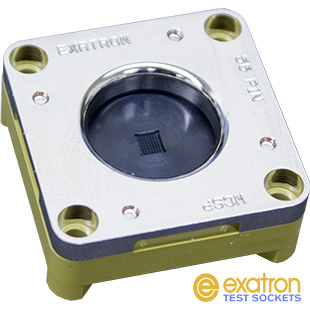

Would blazing fast soak times and remarkably stable temperatures help? Pair the PET-4D with Exatron's Copperhead Thermal Test Sockets.

Solid Copper = Best Thermal Performance